Stretch Film Cost Savings

Welcome to this Tentoma Horizontal Packaging Machine blog which is accompanied by a video called Tentoma Horizontal Packaging Machine (2018) found below in the image link.

PE Stretch Film Cost Savings

The stretch film packaging enables a process where packaging film savings can contribute to a very attractive ROI. Typically film consumption savings between 20% and 60% corresponding to film cost savings between 10% and 50% can be achieved.

Improve - Environmental impact

- Environmental impact

- Working environment

- Carbon footprint

- Green image

PE-Film Cost Savings

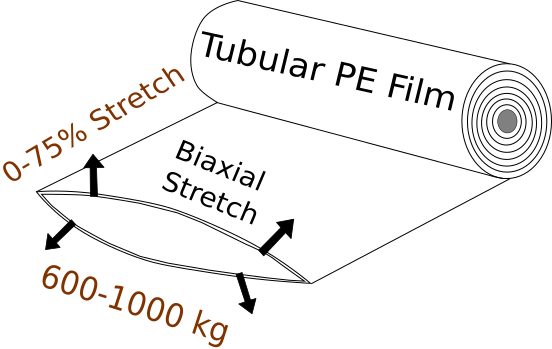

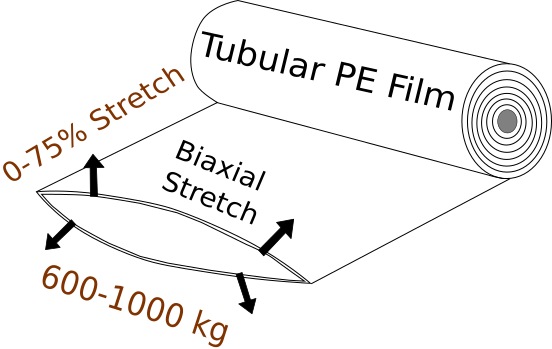

The PE-Film cost savings are achieved with the RoRo StretchPack technology by stretching a tubular Low Density PE-film before applying it on a product. The stretch film will then retract and protect the product. The fact that the film is stretched enables the savings since a reduced amount of film can be applied compared to the size of the product.

10-50% Film cost savings 20-60% Savings in film consumption!

Vertical Stretch Hood (Machine) Experience

Tentoma has accumulated more than 20 years of experience within vertical stretch hood technology from development, service and industrial machine operation activities. This know-how has been converted into a game changing new packaging technology called Horizontal Packaging with the use of Low Density PE-Stretch Film.

The horizontal packaging technology is significantly different from vertical stretch hood which is an EOL packaging technology used for pallet wrapping giving load stability and a 5-sided sealing to protect against contamination.

The RoRo StretchPack technology is targeted for BEOL as well as EOL packaging processes of products that are longer (typically not palletized products) since the stretch film technology from Tentoma allows up to 8 metres long products to be packed with 4-, 5- or 6 sided sealings.

Waterproof Packaging 100% sealed against

100% sealed against

- Storm

- Rain

- Dust

6 sided sealing corresponds to 100% waterproof packaging including full protection against humidity, dust and other form of contamination.

Tentoma can also offer 4- or 5-sided sealing.

Heat Shrink- versus Stretch Film Packaging

When applying stretch film the starting point is to use an amount of film which is smaller than the actual product dimensions. The film is then stretched to cover the product with an adequate stretch percentage depending on the product characteristics such as sharp corners (hard versus soft materials).

In heat shrink the principle is to apply to much film and remove excess PE-film applying heat in a heat shrink tunnel. Apart from applying excess film there is also a high energy consumption since heat shrink systems work continuously whether products are coming or not.

Product segments ideal for horizontal stretch film packaging can be products like building materials, building plates, geotextile or geomembrane rolls, wood blocks, gypsum boards XPS-, EPS plates and other insulation materials.

These products are carefully assessed in a dialogue between Tentoma and the customer in terms of desired outcomes with respect to e.g. sharp corners, ventilation (4- or 5-sided sealing or even perforated PE Film) branding engagement, load stability, film puncture requirements.

The products can then be test packaged to see how the desired outcome is achieved for the customer in order to move forward implementing the machine in either in-line or off-line operation.

BEOL Packaging Machine

BEOL Tentoma packaging machines provide new opportunities for stretch film suppliers and also system integrators/OEM's. These new opportunities can be discovered when looking beyond the traditional applications where PE- film is already being applied. According to CEO Henrik Raunkjaer a film supplier can look for additional supply opportunities to their existing customers “Just because deliveries are made to one EOL process doesn’t mean that there are not opportunities to deliver more film in BEOL packaging processes”. Manufacturers are challenged with new upcoming EUMOS standards and need to improve the way they create load stability in their packaging. This is an opportunity to carefully study new opportunities in BEOL processes and implement module packaging processes using technologies such as RoRo StretchPack by Tentoma.

Module packaging can increase the load stability significantly before the final EOL vertical stretch hood or similar packaging machinery. Watch an example wrapping of the load stability when applying high quality stretch film.

Branding on Industrial Packaging

When the stretch film is applied on a product it will be smoothly closed around the product which enables vast branding opportunities from e.g. logo placements and text messages. Options include:

- Up to 10 different colours

- Precise positioning of logo/text

- Brilliant print quality

- Printable on all side

Increase - Packaging quality

- Packaging quality

- Branding engagement

- Load stability

- Capacity

- Up-time

Tentoma offer unique customer engagement compared to other packaging technologies

Building Material Packaging

RoRo StretchPack machines come with different capabilities depending on the size of e.g. building materials. Please, refer to Downloads in order to learn detailed machine details and find here a quick introduction to the building material products sizes:

- Lengths: 200-8.000 mm

- Widths: 300-2.200 mm

- Heights: 10-1.400 mm

- Product Circumference: max 5.500 mm.

PE-Film Suppliers

The PE-Film suppliers must deliver a Low Density Poly Ethylene Stretch Film with proven stretch capabilities. Tentoma has approved various PE-film suppliers similar to vertical stretch hood film suppliers. They serve their markets locally as well as globally depending on the brand. If in doubt, don’t hesitate to contact sales@tentoma.com for further information.

Operational Packaging Costs and ROI

The ROI (Return-on-Investment) will always be a determining factor when comparing heat shrink packaging to Tentoma Horizontal Stretch Packaging. In the accompanying video in the top, a case study is introduced in order to give a detailed insight of the potential ROI depending on volumes and product sizes. The major savings when implementing Tentoma machines are within the packaging material costs and energy. In many cases the ROI is also affected by improvements in operational activities. A closer look can be taken on issues related to:

Reduce - Operational costs

- Operational costs

- Energy consumption

- Fire risk

- Film cost by 10 – 50%

- Film waste

- Extraordinary handling including manual labour

- Unexpected down-times

- Recovery times

- Maintenance costs

- Excess quality inspections

Tentoma is a Manufacturer of Packaging Machines

Tentoma was originally founded by Frank Bruhn in 2011 as a service- and specialist company within vertical stretch hood technology. In 2014 Mr. Bruhn developed the horizontal stretch film technology and launched the first Tentoma machines early 2015. In 2017 a AAA+ rated investor, Danish Growth Fund joined Tentoma in order to support a strategic global expansion with a unique new packaging technology based on a solid machine installation references all over Europe across various segments.